Sumitomo Rubber Industries, Ltd. (SRI) and Tohoku University teamed up to increase the speed of 4-Dimensional Computed Tomography (4D-CT) a thousand-fold, making it possible to observe rubber failure in tires in near real-time.

This breakthrough will accelerate the development of new tire materials to provide super wear resistance, greater environmental friendliness, and longer service life. It will also aid significantly in the advancement of smart tires.

SRI initially developed 4D-CT as part of the ADVANCED 4D NANO DESIGN, a new materials development technology unveiled in 2015 that enables highly accurate analysis and simulation of the rubber’s internal structure from the micro to nanoscale. This analysis ultimately leads to enhanced rubber wear performance in terms of fuel efficiency, wet grip, and wear resistance.

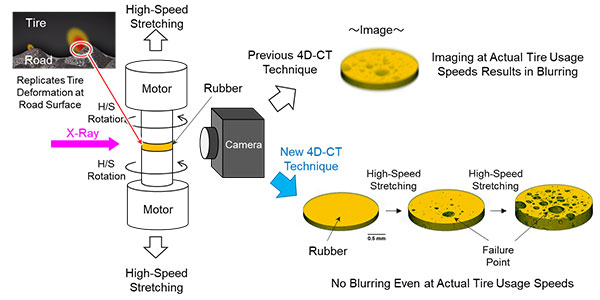

Since the birth of ADVANCED 4D NANO DESIGN, SRI has undertaken new materials development using the technology available at the SPring-8 synchrotron radiation research facility. However, the existing 4D-CT technique still took several seconds to capture a single 3D image.

Wataru Yashiro, associate professor at Tohoku University, had previously developed a new method to produce higher quality CT images within milliseconds. The technology, which used intense synchrotron radiation, made the breakthrough feasible. It became possible to observe rubber failure as it occurs at varying speeds, allowing a better approximation of a tire’s rubber wear.

A schematic of high-speed 4D-CT imaging system & resulting 3D image of rubber failure in progress. ©Sumitomo Rubber Industries, Ltd.

“As a result of this research, we have increased the speed of imaging by approximately a thousand-fold, meaning that a 3D image can now be captured in around 1/100 of a second,” said Yashiro.

Looking ahead, SRI hopes to use this technology in conjunction with machine learning and other advanced data processing techniques to analyze the enormous amounts of data that this imaging technique will generate. On the collaborative side, SRI and Tohoku University will continue to serve as participants in the Japan Science and Technological Agency’s Core Research for Evolutionary Science and Technology Program (CREST).

Publication Details

“High-speed rotating device for X-ray tomography with 10 ms temporal resolution”

Authors:Ryo Mashita, Wataru Yashiro, Daisuke Kaneko, Yasumasa Bito, and Hiroyuki Kishimoto

Journal of Synchrotron Radiation

DOI: 10.1107/S1600577520014666

Contact

Institute of Multidisciplinary Research for Advanced Materials (IMRAM), Tohoku University

Email: wyashiro[at]tohoku.ac.jp