Research Division

Research Keyword

High-temperature Physical Chemistry of Materials FUKUYAMA Lab

- Hiroyuki FUKUYAMA, Professor

- Keywordmaterials processes / chemical thermodynamics / thermophysical properties of hightemperature melts / crystal growth

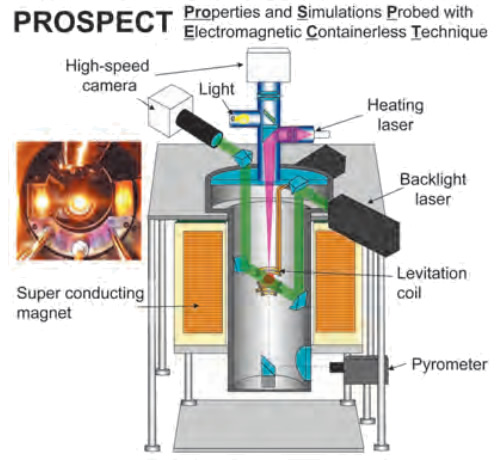

High-temperature processes and measurements of materials

Fukuyama laboratory studies novel material processing based on chemical thermodynamics with high-temperature thermophysical property measurements. Currently, we are developing new crystal growth processes to bring a breakthrough in nitride-semiconductor devices, which are promising materials for next-generation optical devices applied in environmental, medical, bio and information technologies fields. Database of thermophysical properties of materials is needed for modeling heat and mass transports in materials processes. The world’ first thermophysical property measurement system has been developed in our laboratory, which enables accurate measurements of heat capacity, thermal conductivity, emissivity, density and surface tension of high-temperature melts, utilizing electromagnetic levitation in a dc magnetic field.

High-temperature Physical Chemistry of Materials

Base Materials Processing UEDA Lab

- Shigeru UEDA, Professor

- Keywordsteelmaking / ferrous metallurgy / chemical equilibrium / reaction kinetics / material recycling

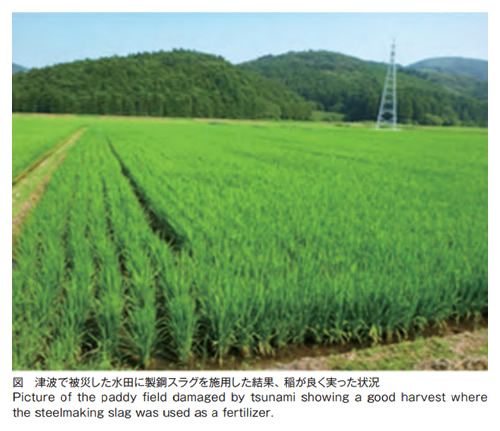

New development of steelmaking process

The steelmaking process has an extremely important role in supporting the development of an eco-friendly society and it becomes to an age of technical innovation. For the research and development of this field, we have to consider the following points on four different scales: Giga scale = Consider the global impact of the extraction process, Mega scale = Enhance the performance of reactors, Micro scale = Identify the controlling factors of the reaction rate and Nano scale = Control the mass transfer of molecules. At Ueda laboratory, the researches based on the above four points are being carried out in the field of steelmaking, which is a core process used to produce high-quality steel.

Base Materials Processing

Powder Processing for Functional Materials KANO Lab

- Junya KANO, Professor

- Keywordpowder technology / grinding / mechanochemical reaction / recycle / hydrogen / rare metal / simulation

Development of new functional powder processing and optimum design of powder processing by numerical simulation

Development and manufacture of high functional materials have been actively made, and most of those raw materials, intermediate products and final products are particulate materials. The properties of the high functional materials are greatly dependent on the particle packing structure in the materials as well as those chemical compositions. The particle packing structure is also highly dependent on the particle properties and characteristics such as particle size and its distribution of the particles, which depend on their preparation processes. Therefore, in order to obtain the function desired, first of all, the preparation process of the particles as a raw material should be elaborately controlled, and then the powder processing such as mixing, filling, forming and composite must be controlled exquisitely.

In our laboratory, we are carrying out development of computer simulation method for control of powder processing. Optimizing the powder processing by the simulation is performed for energy saving and resource saving. In addition, we are developing processes for recycling of metals from urban mines and for hydrogen energy generation from biomass and plastics by using the mechanochemical effects which are obtained in the grinding process.

Powder Processing for Functional Materials

Energy Resources and Processing KIRISHIMA Lab

- Akira KIRISHIMA, Professor

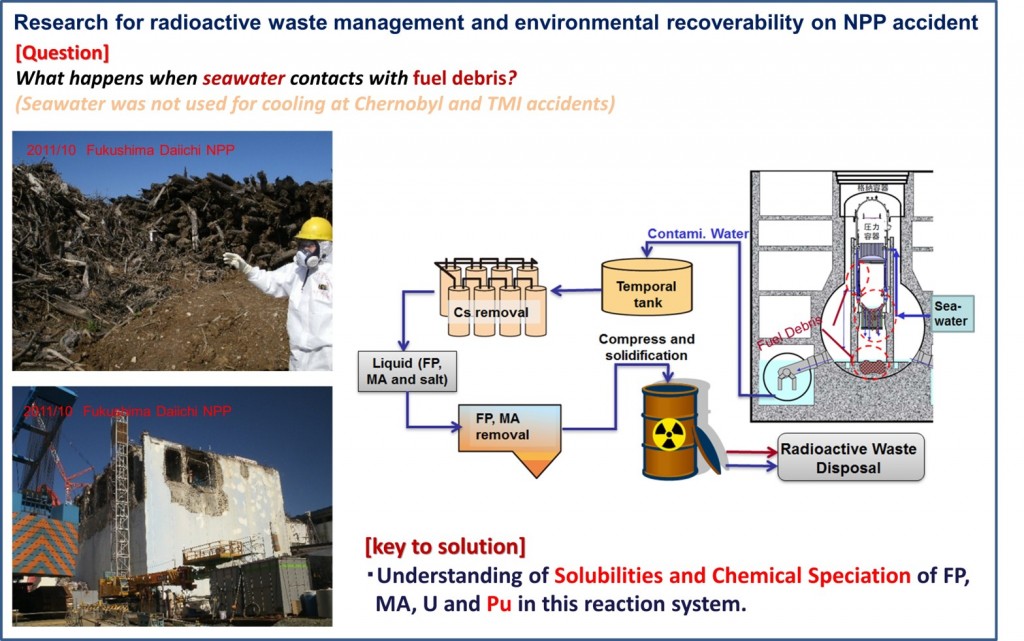

- KeywordRadiochemistry/ Nuclear waste management/ Decommissioning/Solution Chemistry

Research on Nuclear Waste Management and Nuclear Facility Decommissioning by Radiochemistry

Nuclear energy is one of the most important energy resource of our modern society, therefore, it is strongly demanded to make nuclear fuel cycle more reliable. Also, decommissioning of the severely damaged reactors by Fukushima NPP accident in 2011 and recovery of the contaminated environment, are urgent issues in Japan. To respond these demands, our group investigate chemistry of nuclear fuel debris and leaching behavior of actinides in it by synthesizing simulated fuel debris with actinide tracers. Furthermore, we develop novel and unique nuclear waste solidification processes using functional aluminum silicate minerals as fixation agent.

Energy Resources and Processing

Chemistry of Energy Conversion Devices HONMA Lab

- Itaru HONMA, Professor

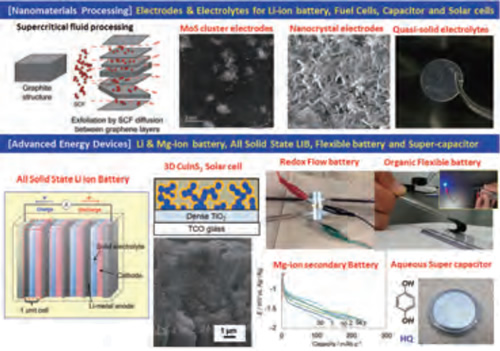

- Keywordrenewable energy/nanotechnology/lithium ion secondary battery/fuel cell/solar cell

Energy technology innovations via advanced nanotechnology and nanoscience

Honma laboratory investigates frontier nanotechnology and nanosciencefor innovationsonadvancedrenewableenergy technology, which contribute to a global sustainability and low emission society. The green technology would be most importantissues what scientistschallengeforglobal sustainability in the 21st century.

Particularly, we focus on studies in fine chemistry of advancedenergydevicesemployingadvancednanotechnologies; 1. monoatomic-layered materials, 2. Nanocrystalline electrode materials,3.organicnanomaterials,4.highionconductive solid state electrolyte, 5. nanoporous/mesoporous materials 6. supercritical fluid processing, 7. spectroscopy analysis using synchrotron radiation.

In depth studies on these advanced functional materials and characterization techniques may result in innovations of lithium ion secondary batteries with high energy & high power density, low cost fuel cell for future smart grids, and compound semiconductor solar cells achieving both high conversion efficiency and environmental friendly.

Chemistry of Energy Conversion Devices

Metallurgy and Recycling System for Metal Resources Circulation SHIBATA E. Lab

- Etsuro SHIBATA, Professor

- KeywordNon-ferrous Metallurgy /Metal Resources Circulation/Recycling/Waste Treatment

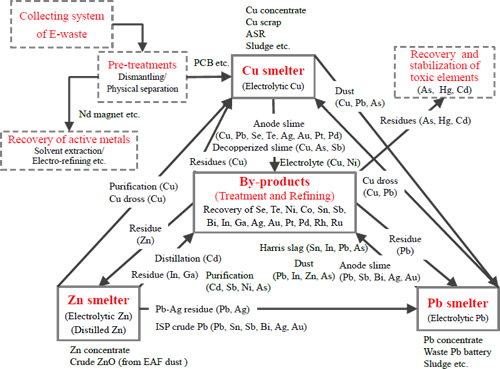

Establishment of Metal Resources Circulation System Based on Non-ferrous Smelting Industry

Non-ferrous smelting industry is necessary for achievement of the resource circulation society. In the future, the use of various electrical and electronic devices is expected to increase with growth of population in the world. To secure metal resources continuously, it is necessary to recycle metals used in waste products.

The main research aim is to establish the metal resources circulation system based on the non-ferrous smelting industry. Research activities including non-ferrous metallurgy along with mineral processing beyond the traditional framework are intended to achieve the high efficiency circulation of metal resources and environmental conservation in the future. Researches for smelting processes for primary and secondary resources, treatments of by-products and stabilization of environmental load elements, etc. are conducted.

Linkage among copper, lead and zinc smelters to recover valuable metals from various type of resources

Linkage among copper, lead and zinc smelters to recover valuable metals from various type of resources

Metallurgy and Recycling System for Metal Resources Circulation

Atomic Site Control in Inorganic Materials OMATA Lab

- Takahisa OMATA, Professor

- Keywordinorganic materials / power generation devices using natural energy / ion-exchange and intercalation / ion-beam

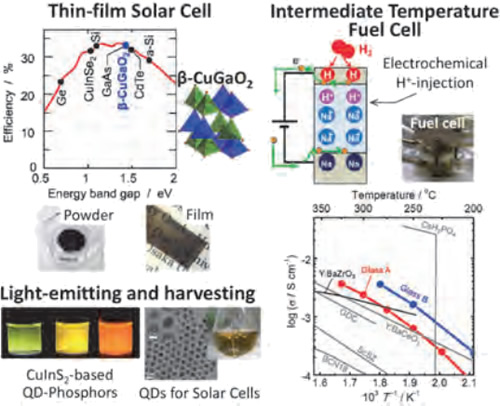

Creation of environmentally-conscious materials based on atomic site designing

Most innovations have been triggered by advent of new materials, and the present energy, environmental and resource issues are expected to be solved by new materials. We focus on to explore new materials and their synthesis routes using ion-exchange and ionic intercalation techniques.

Proton conducting phosphate glasses working at intermediate temperatures and narrow gap oxide semiconductors applicable in visible and NIR regions have been recently developed. Simple and safe synthesis routes to cadmium-free quantum dot phosphors and colloidal indium arsenide quantum dots for solar cells were also found out. Thin-film solar cells, fuel cells and light-emitting devices using those materials are now developing.

Atomic Site Control in Inorganic Materials

Environmental-Conscious Materials Processing NOGAMI Lab

- Hiroshi NOGAMI, Professor

- Keywordironmaking / process simulation / transport phenomena / multiphase / reaction kinetics / thermal engineering

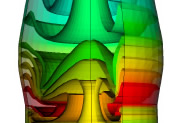

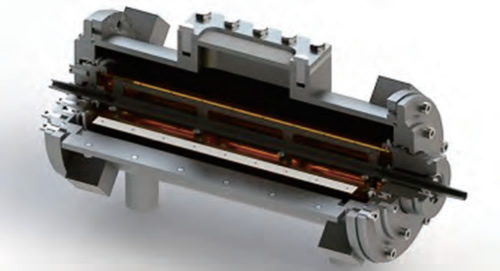

Development of novel material processing through process analysis based on reaction kinetics

For the reduction of energy and material resources consumption in base metals production, improvement of process efficiency, enhancement of flexibility to raw material resources and development of novel processes are required. One of our approaches for this issue is numerical process simulation to reproduce and evaluate the materials production processes, based on the theories of multiphase fluid dynamics, reaction kinetics, thermodynamics, thermal fluid engineering, transport phenomena, powder technology, and so on. Using the results of the process analysis and the fruits obtained through the modeling of unit operations, we are trying to develop novel material production technology. Additionally we are trying to develop new processes for recovery and storage of thermal energy.

High-performance heat exchanger with boundary layer control

High-performance heat exchanger with boundary layer control

Environmental-Conscious Materials Processing

Materials Separation Processing SHIBATA H. Lab

- Hiroyuki SHIBATA, Professor

- Keywordsilicates / thermophysical property / solidification process / refining process

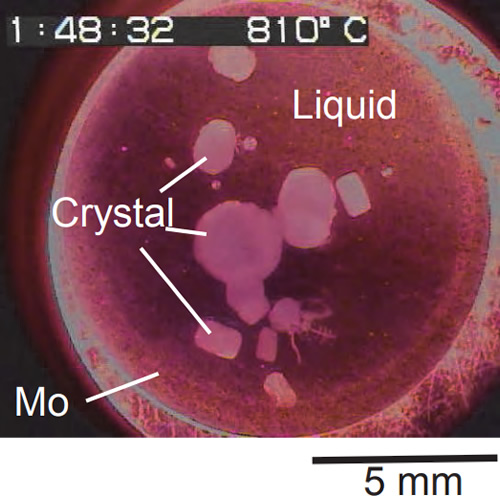

Physicochemical approach to interfacial phenomena at high temperature for high efficiency materials processing

Recycling, refining and solidification processes of materials are important to sustain high efficiency process for manufacturing products. Each material separation process is governed by many chemical and thermophysical properties of materials and interfaces among materials. Functions of the materials should be clarified from micromechanism of each phenomenon to develop high efficiency processes for materials separation as well as crystal growth by means of in-situ observation and measurements especially at high temperature.

Crystallization of lithium silicate on the molybdenum substrate

Crystallization of lithium silicate on the molybdenum substrate

Materials Separation Processing